- About Us

- Products

- Technology & Services

- Coiled Tubing Multi-stage Fracture Technology

- Coiled Tubing Drilling Technology

- Coiled Tubing Cutting Technology

- Coiled Tubing Wellbore Cleaning Technology

- Coiled tubing fishing technology

- Staged fracturing technology of open-hole ball-throwing sliding sleeve

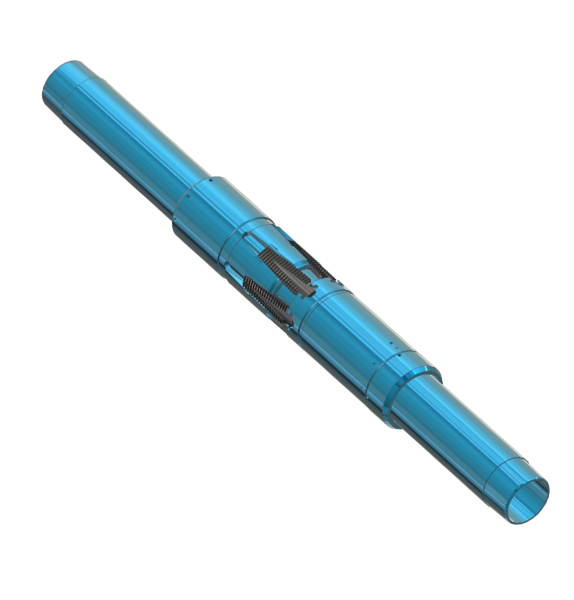

- Plug-and-Perf System

- Full bore sliding sleeve fracturing technology

- News

- Contact Us